As part of Autodesk’s annual Design & Make It Real program, the Make It Home affordable housing challenge invited students to reimagine how design and construction can strengthen communities through innovative, affordable housing solutions. The challenge is one of several initiatives within the program that encourage young people to apply design thinking to real-world problems in the built environment—while gaining early exposure to the tools and mindsets shaping today’s architecture, engineering, and construction industry.

This year, we’re sharing these stories during Construction Inclusion Week and Careers in Construction Month, a time to celebrate the diverse voices, perspectives, and pathways shaping the future of building. Each feature in this series pairs a student designer with an industry mentor whose insights illuminate how Design and Make skills and professional practice come together to drive meaningful change.

Today’s story brings together Paul Blandini, Vice President of Business Strategy & Operations at Autodesk, and Sai Saatvik Katakota, a rising junior from Ballantyne Ridge High School in Charlotte, North Carolina. His project, Modular 3D-Printed Affordable Housing – Combating Homelessness Through Innovation and Sustainability, reimagines wildfire-resilient, rapidly deployable homes as a pathway to dignity, stability, and long-term community impact..

About the design

Modular 3D-Printed Affordable Housing responds to both wildfire devastation and chronic homelessness in Sylmar, Los Angeles. Inspired by the January 2025 “Hustle” wildfire and the lack of permanent, dignified housing for displaced residents and veterans, Sai designed a replicable modular system using 3D-printed, fire-resistant concrete.

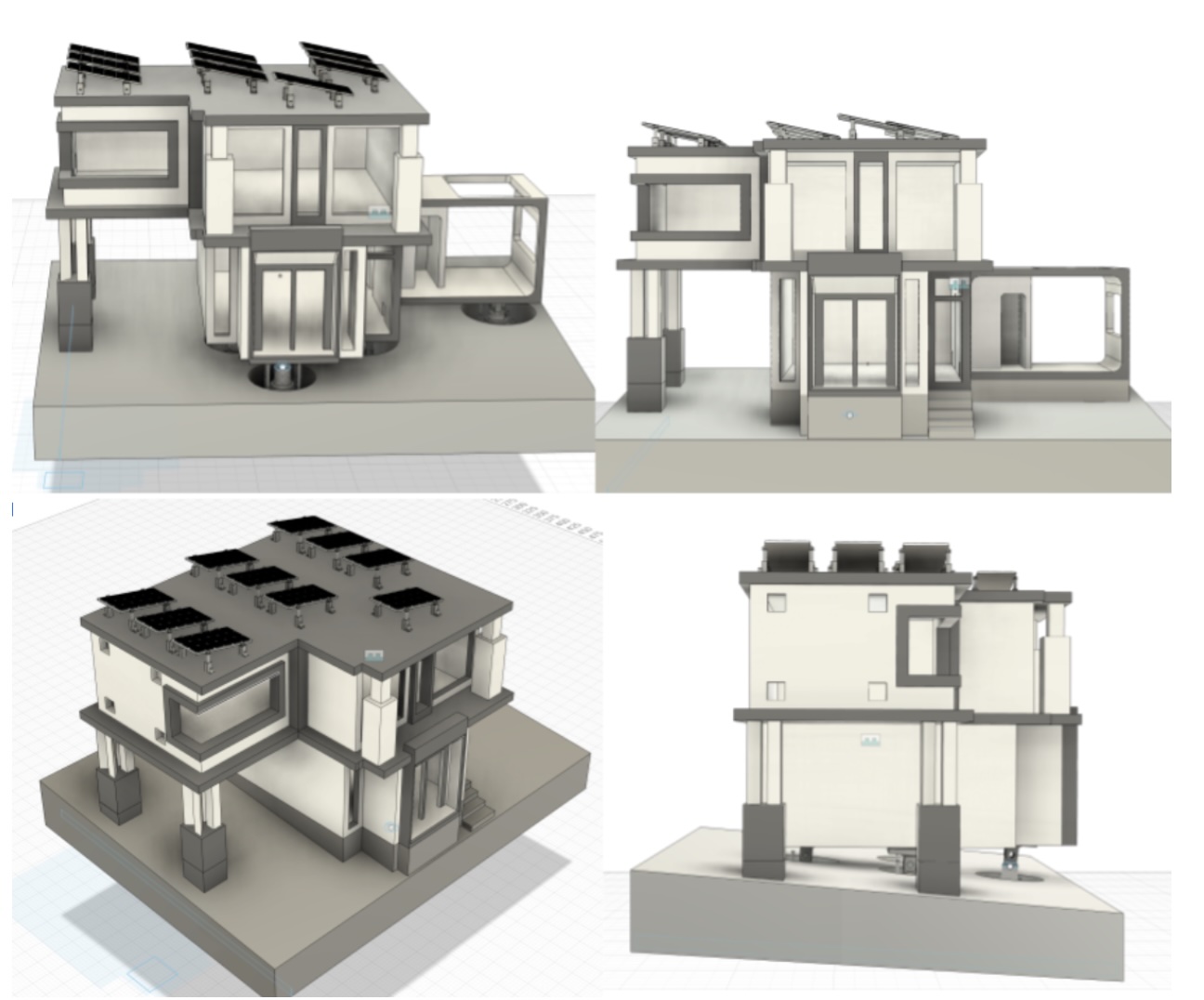

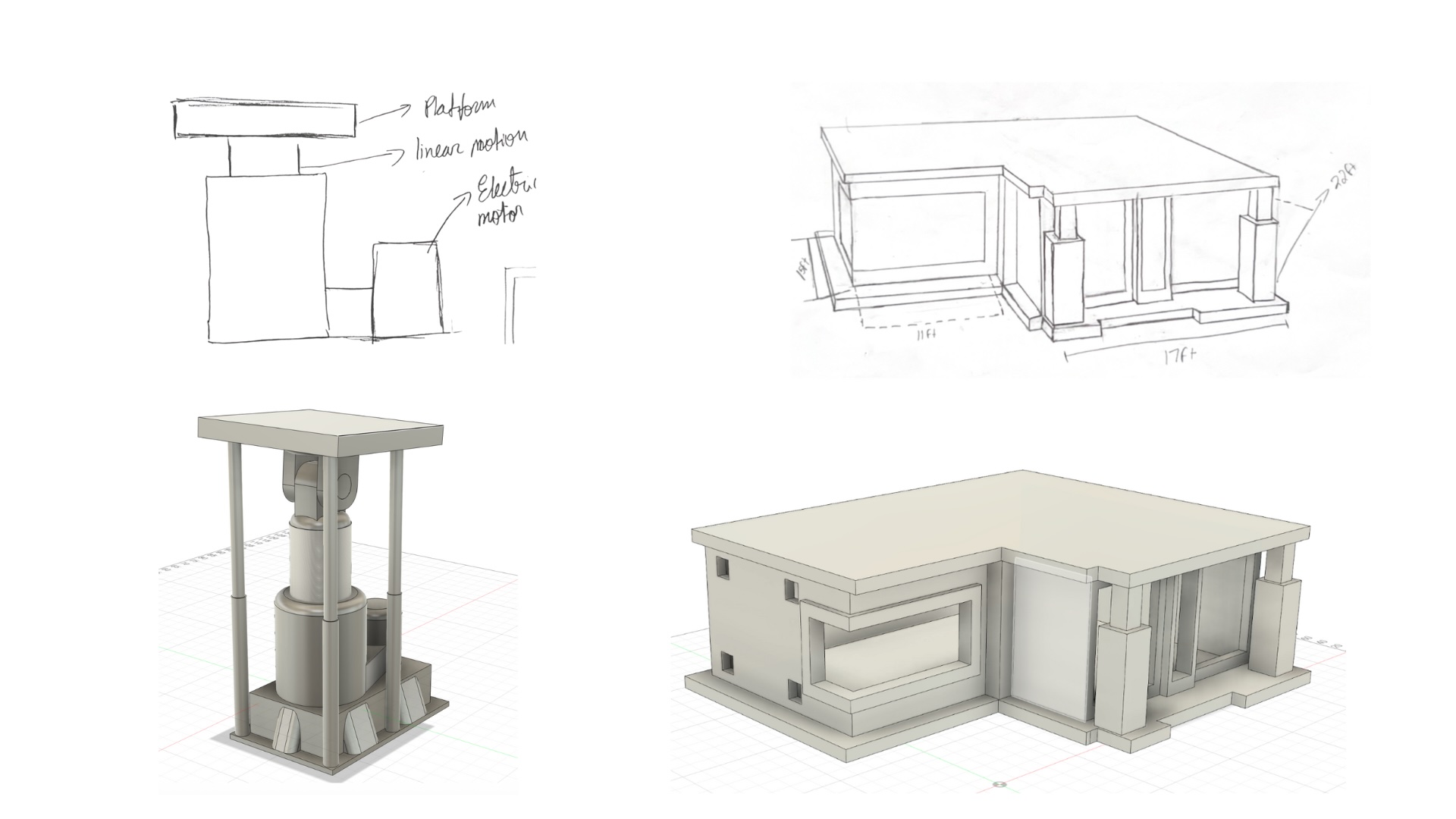

Three prefabricated unit sizes can be configured horizontally or vertically to adapt to family needs. Remote-adjustable linear actuators level homes on sloped terrain, while self-adjusting solar panels track the sun for maximum renewable energy output. Skylights and large windows reduce reliance on artificial lighting, and integrated Wi-Fi access supports education, telehealth, and job opportunities. A combination of government grants and modular pricing keeps costs within reach for low-income or unhoused individuals.

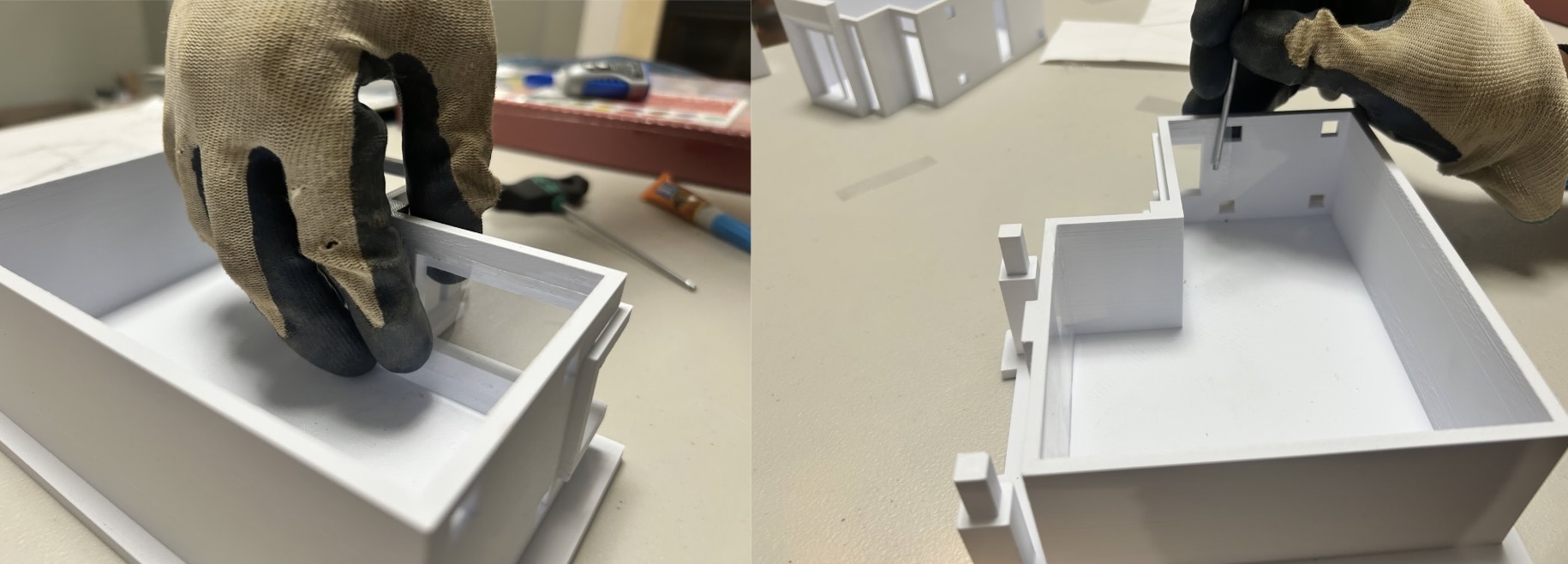

Sai validated his design using Autodesk Fusion simulations, wrote custom code for solar panel motion using inverse kinematics, and built a highly detailed 1:50 scale 3D-printed physical model, demonstrating professional-level constructability and presentation skills.

Mentor Spotlight: Paul Blandini on innovation, empathy, and the future of building

A longtime champion of education and workforce development in the construction industry, Paul Blandini has dedicated his career to expanding access to opportunity. As Vice President of Business Strategy & Operations and a founding member of the construction business at Autodesk, he bridges technology, industry transformation, and talent development.

Paul helped launch the original Make It Real program in 2017 (now Autodesk’s Design & Make It Real) to expose students to professional tools, real-world design challenges, and career pathways into Design and Make industries. His passion lies in helping young people, especially those who might not initially see themselves in this field, realize their potential as future builders and innovators.

Favorite Project

Modular 3D-Printed Affordable Housing – Combating Homelessness Through Innovation and Sustainability

Student Designer: Sai Saatvik Katakota

Project Site: Sylmar, Los Angeles, California

What stood out to you about Sai Saatvik Katakota’s project?

What immediately struck me was how comprehensive Sai’s thinking was. He didn’t just design a building , he designed a system for dignity. His modular, 3D-printed housing concept tackled two interconnected crises head-on: wildfire displacement and chronic homelessness. That kind of empathy-driven systems thinking is exactly what we need in this industry.

From the fire-resistant concrete to the solar tracking panels and adjustable foundations, every decision was rooted in practicality and purpose. And the fact that a high school student designed this, validated it in Fusion, and even coded the solar panel motion himself? That’s next-level initiative.

What I also appreciated deeply was Sai’s hands-on craftsmanship in building a physical scale model with precision and care. In construction, the ability to think digitally and physically is invaluable. Designing for constructability means understanding how materials come together, how systems align, and how details translate from screen to site. Sai demonstrated that brilliantly.

It’s the perfect example of how digital literacy, when combined with craftsmanship and compassion, can lead to meaningful innovation.

Why was judging this contest personally meaningful for you?

Education has always been a personal calling for me — I’m the son of a public school teacher, so I grew up seeing both the promise and the challenges of our education system. What drives me is creating pathways for students who might not otherwise see themselves in construction or design careers.

When I look at projects like Sai’s, I see what happens when we give young people access to professional tools and real-world challenges. They rise to the occasion. Sai wasn’t solving a theoretical exercise; he was imagining how modular design, robotics, and sustainable materials could transform how communities recover from disaster. That’s powerful. It’s why I love judging this contest — it shows the future of our industry is in good hands.

What inspiration did you take away from the student entries overall?

This year reminded me that the next generation already understands the kind of transformation we talk about daily in the construction industry — sustainability, data-driven design, and inclusivity. They’re thinking beyond “how do we build faster?” and asking “how do we build better, fairer, and smarter?”

Sai’s project stood out because it wove together engineering, coding, and social consciousness. He found a way to merge what he’s learning in robotics with what he cares about as a citizen. That kind of mindset is gold — and it’s exactly what will close the talent and innovation gaps in our field.

What advice would you give to young people entering this field?

Be curious and be courageous. Learn how buildings come together from every angle — design, materials, fabrication, and data. But also, never lose sight of who you’re building for. The best designers listen first.

And start early. Tools like Autodesk Tinkercad and Fusion are giving students like Sai a running start into professional workflows. The earlier you connect your creativity to real-world problems, the more impact you’ll have when you enter the workforce.

Any final thoughts?

Sai’s project gave me real hope. It represents what I’ve always believed — that the future of construction is not just about efficiency or automation, but about empathy, sustainability, and opportunity. Watching young people apply technology to rebuild communities after loss, and to do so with such imagination, reminds me why we invest in programs like Autodesk Design & Make It Real. They’re not just learning software; they’re learning what it means to build a better world

Student Spotlight: Sai Saatvik Katakota on innovation, resilience, and building with purpose

Tell us about your submission. What inspired your project?

Since I’ve lived in the US, the frequency of wildfires in California has been a constant source of disaster. These fires have destroyed homes and displaced thousands, forcing them to rebuild from the ashes. Every year, I watch the news and see hundreds of families left stranded on the streets with no belongings, their homes reduced to rubble. Despite this devastation, the houses are rebuilt, only for the cycle to repeat. I couldn’t help but wonder why the same materials are used repeatedly, even though using them means the houses will eventually burn down again. Using stronger, fire-resistant materials could drastically change the outcome for entire neighborhoods, protecting homes and belongings from flames year after year.

To break this vicious cycle, I began researching alternative materials to replace wood, which is the most commonly used building material and one of the main reasons why houses are so flammable. After thorough research, I discovered the use of concrete for building homes. Although building houses out of concrete is not very common in the US, it’s not an unfamiliar practice globally. The main issue was that concrete construction involves high labor costs, which is a drawback. Fortunately, during my research, I found an alternative: 3D-printed concrete houses. That’s when I started to see the bigger picture, and before I knew it, I was designing modular, 3D-printed, affordable housing aimed at addressing multiple issues.

What did this project teach you about the role of architects, engineers, and builders?

This project highlighted the vital role of architects, engineers, and builders in solving big social challenges in our society. Working on the project showed me that without their expertise, some of people’s most pressing problems would remain unsolved. They are quite literally saving lives. They don’t just design or construct; they actively solve critical societal issues that are detrimental to humanity. I hope they continue to find solutions and help overcome social challenges, and I aspire to become a capable engineer who can make a similar impact in the future.

How did feedback shape your final design?

My final design was greatly influenced by the input I got from my cousin, who is presently enrolled in the Rochester Institute of Technology to complete his Ph.D. His guidance played an instrumental role in shaping my final design and allowed me to identify weaknesses in my project that would have gone unnoticed without his knowledge. Not only did his feedback provide an industry professional’s perspective, but it also deepened my understanding of real-world engineering and its requisites. Without him, I wouldn’t have been able to create such a competitive and well-developed project.

Looking ahead

During Construction Inclusion Week and Careers in Construction Month, we celebrate stories like these—where mentorship meets imagination, and where the next generation of designers and builders are not just imagining a more inclusive future, but actively constructing it.

Stay tuned for more Student + Mentor Spotlights from Autodesk’s Design & Make It Real program, featuring inspiring conversations between professionals and students who are redefining what it means to design and make a better world.

You can find previous stories here.

The post Designing After Disaster: A conversation between Make It Home student winner Sai Saatvik Katakota and Paul Blandini, Autodesk appeared first on Digital Builder.